Explore What Drives Us

Beyond the Surface: Discover What Drives Us.

This is where you get to know Kraftman Tooling up close—through the people, the projects, and the progress.

Browse our product gallery, explore real-world success stories, stay updated with news and events, and dive into insights from our blog. Whether you’re here to be inspired, informed, or simply curious—this is the place to explore the heart of our brand.

News & Event

Skill Development Initiatives Announced

The PlastIndia Foundation launched a nationwide upskilling campaign aimed at training 50,000 youths in…

Automotive Plastic Trends Revealed

At AutoPlast India, the focus was on lightweight composites and EV-friendly plastics, underlining the…

Startups Shine at Innovation Pavilion

Plastic Tech India introduced a dedicated space for startups, where young innovators showcased rapid…

Global Giants Eye Indian Market

Major international players, including Engel, Arburg, and Haitian, announced expansion plans in India during…

Mold-Making Tech Gets Smarter

At the Gujarat Plastic Expo, smart mold-making tools using AI and IoT integration were…

Green Plastics Take Center Stage

Sustainability stole the spotlight at PlastIndia, with several companies unveiling bio-based polymers and eco-friendly…

IndiaPlast 2025 Sets Record Attendance

The IndiaPlast Fair drew massive crowds this year, with over 80,000 visitors and 1,500…

India’s Export Potential in Focus

Industry leaders at the Delhi Plast Show emphasized India’s growing influence as an export…

Success Story

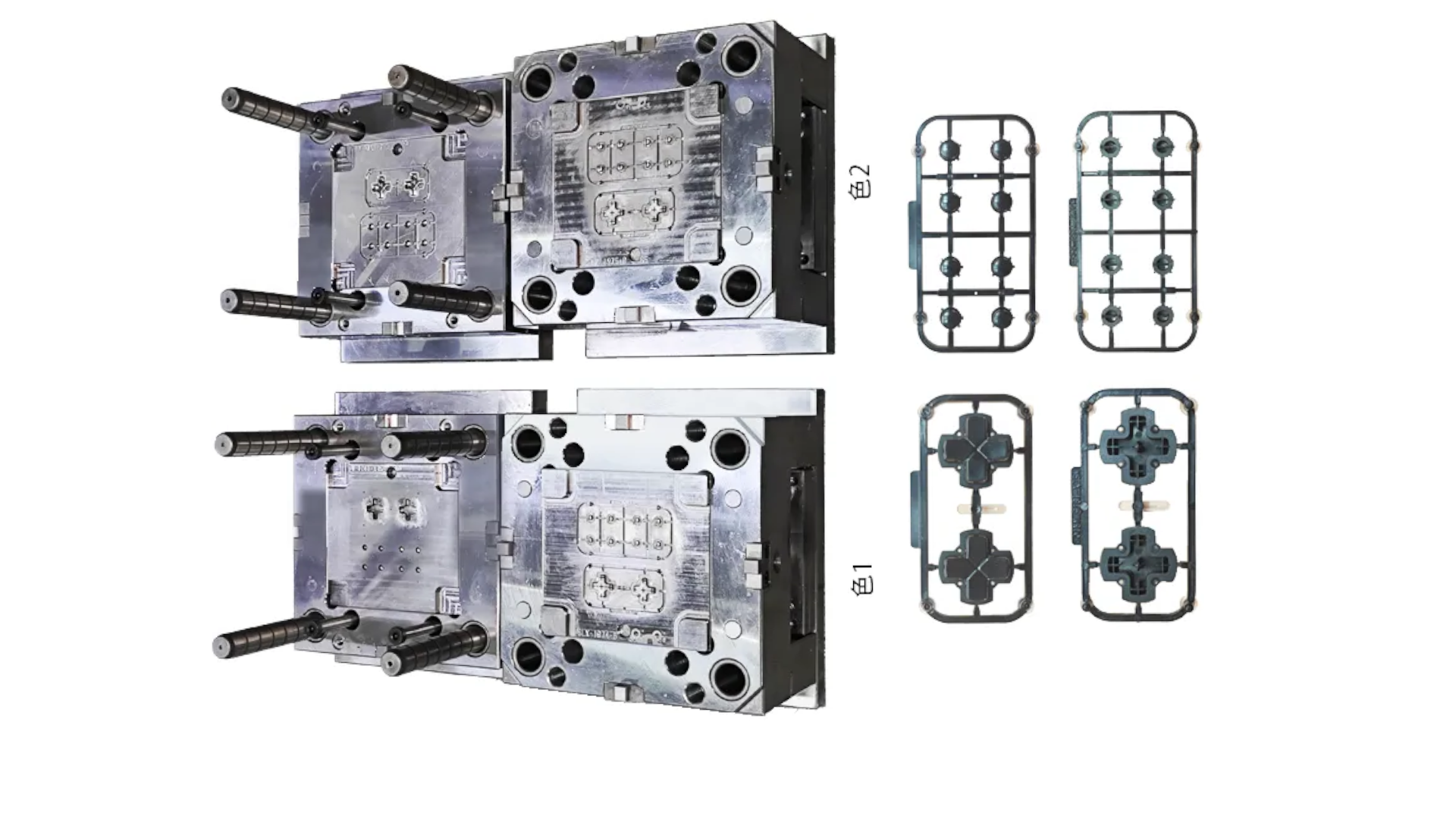

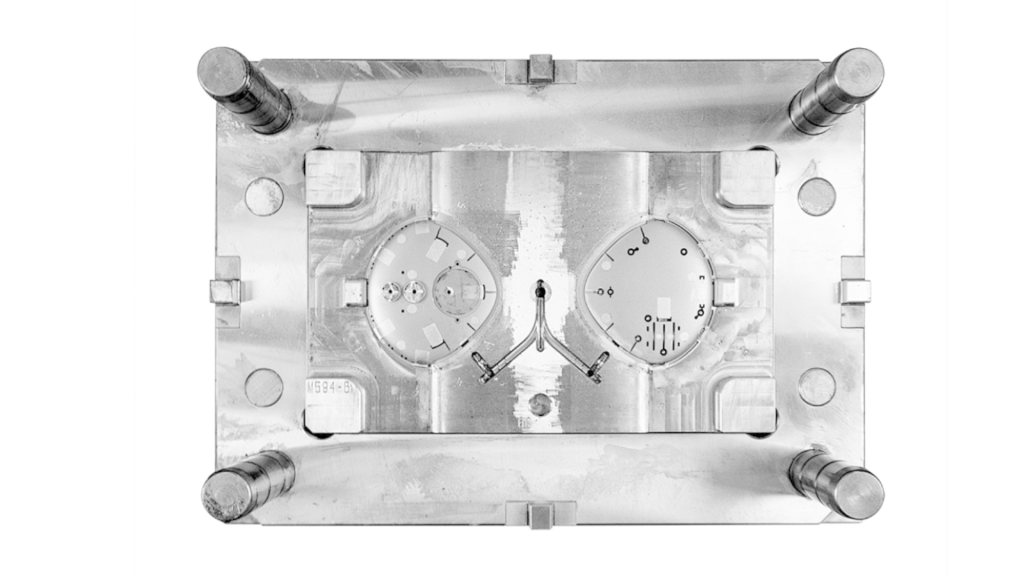

Turning Complex Problems into Smart Solutions

From Prototype Panic to Award-Winning Product

A client came to us in crisis with their ultra-light, water-resistant fitness tracker. The original housing design had such tight tolerances, their supplier gave up. We stepped in, re-engineered the mold using high-performance polycarbonate, and tackled tricky undercuts with a custom gating system.

Result? 50,000 flawless units delivered in 6 weeks—25% faster than planned. The product launched on time, won a design award, and the client said, “You didn’t just save the project—you made it better.

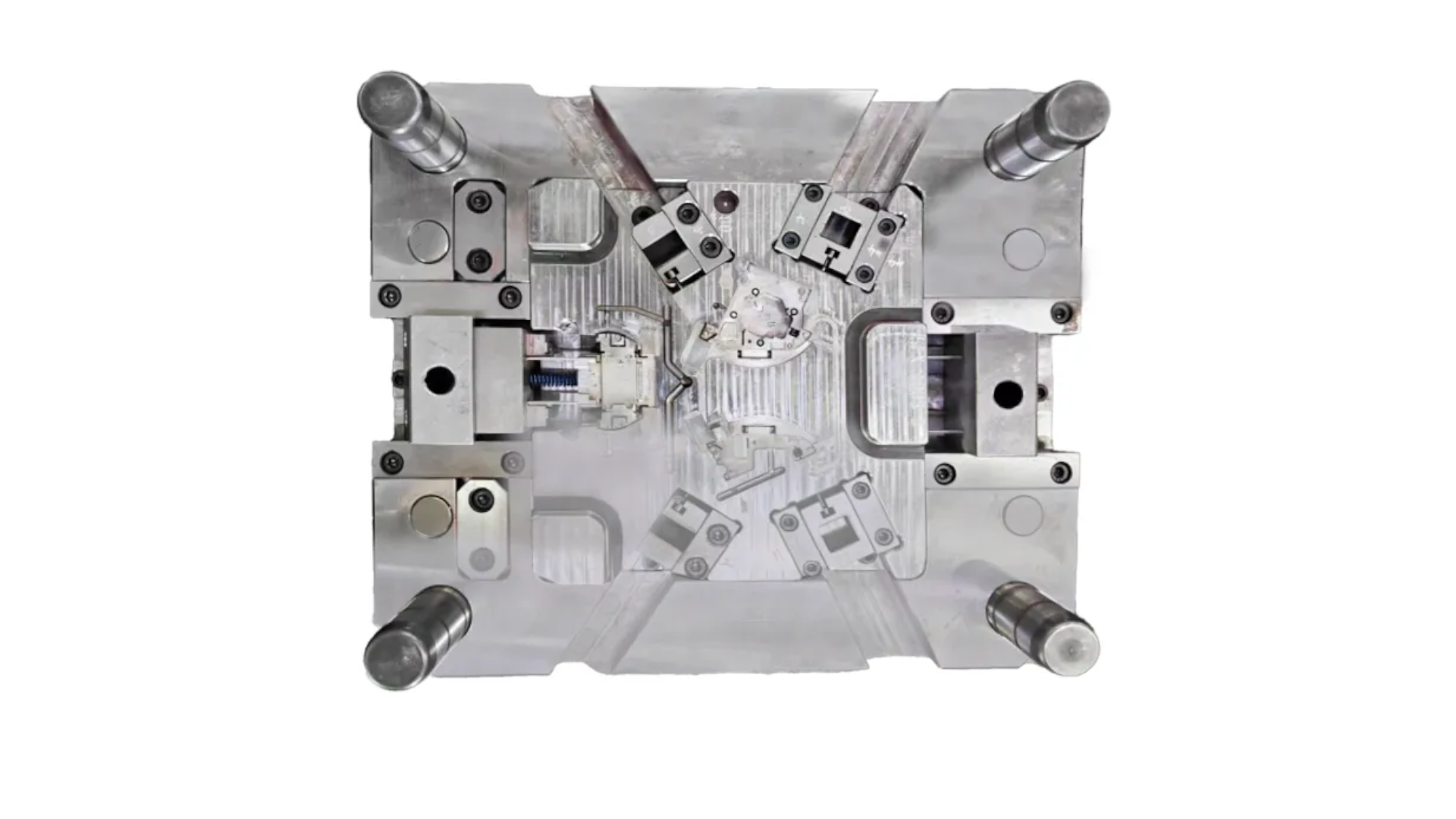

Scaling Smart: The IoT Hub That Made It Big

A startup’s smart home hub went viral after crowdfunding success—but their 1,000-unit prototype needed to scale to 100,000 sustainably and fast. We optimized their mold for mass production and sourced a bio-based polymer without compromising quality.

Result? Premium finish, perfect snap-fits, and lightning-fast delivery. The CEO said, “You made us look good.” And the shelves? Empty in no time

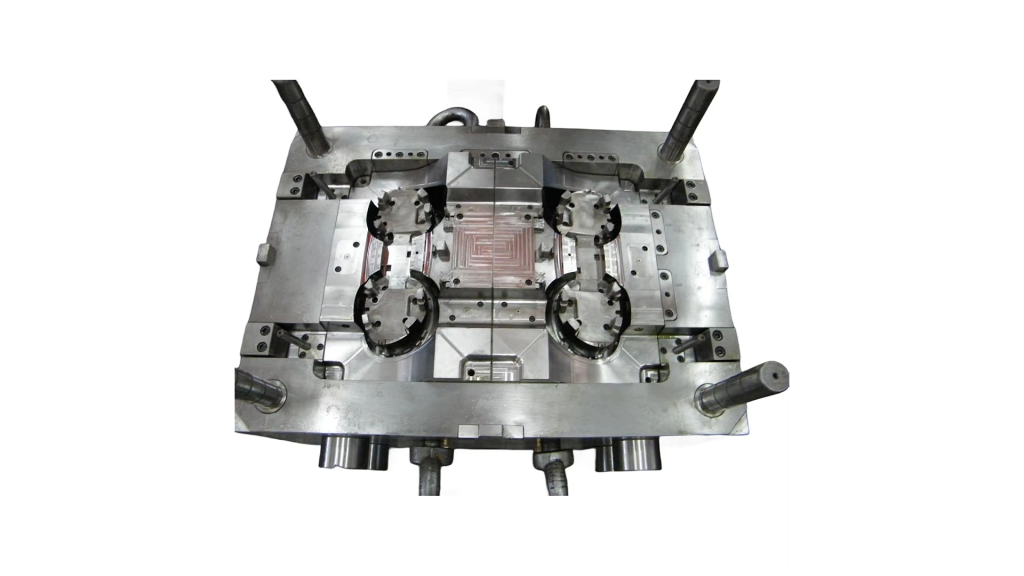

Tough Mold for a Tough Job

An industrial electronics firm needed a housing that could withstand extreme heat, dust, and vibration. We rapidly prototyped in 3D, chose a glass-filled nylon blend, and nailed UL certification—weeks ahead of schedule.

Result? A rugged, reliable control module now powering machinery around the world. The client told us, “We couldn’t have launched without you.”

”

The Lighting Solution That Stood the Heat

A lighting manufacturer came to us with a challenge: produce sleek, heat-resistant lamp housings for high-end commercial buildings. The catch? Tight aesthetics, tricky ventilation slots, and high thermal demands. We used a custom heat-stable polymer and refined the mold for razor-sharp detail.

Result? Seamless parts, zero warping, and a thrilled client who said, “You helped us shine in every sense.”