BRINGING IDEAS TO LIFE

BRINGING IDEAS TO LIFE

BRINGING IDEAS TO LIFE

BRINGING IDEAS TO LIFE

Design & Engineering

Design & Engineering is where every great product begins. It’s the essential process of transforming an idea into a functional, manufacturable, and market-ready solution. From initial sketches to detailed 3D models, we combine creativity with technical expertise to shape innovative designs that perform in the real world. This phase involves selecting the right materials, optimizing for production, and ensuring every detail aligns with the final application. It’s where vision meets precision—and where your product truly starts to take form and function.

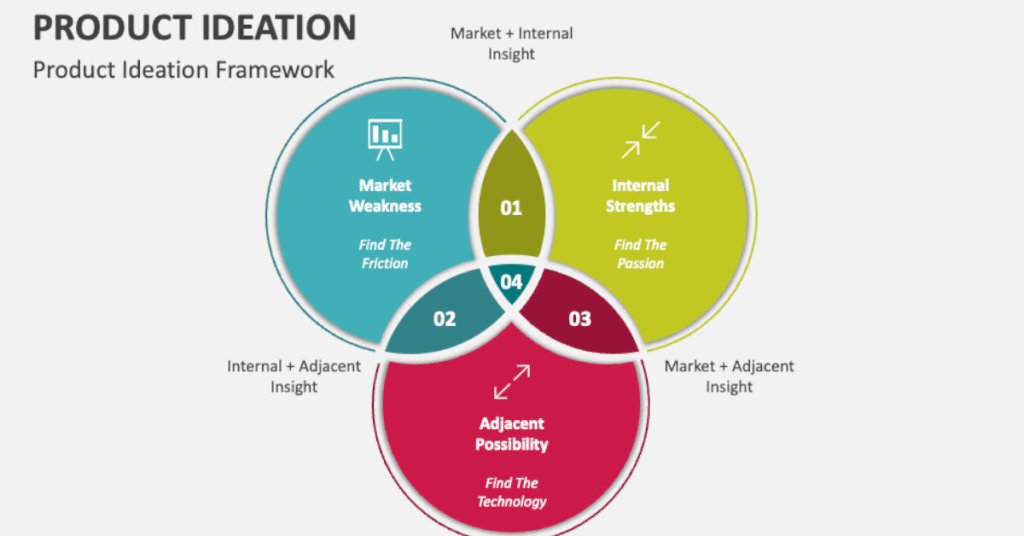

IDEATION

What's all about?

Design & Engineering is where every great product begins. It’s the essential process of transforming an idea into a functional, manufacturable, and market-ready solution. From initial sketches to detailed 3D models, we combine creativity with technical expertise to shape innovative designs that perform in the real world. This phase involves selecting the right materials, optimizing for production, and ensuring every detail aligns with the final application. It’s where vision meets precision—and where your product truly starts to take form and function.

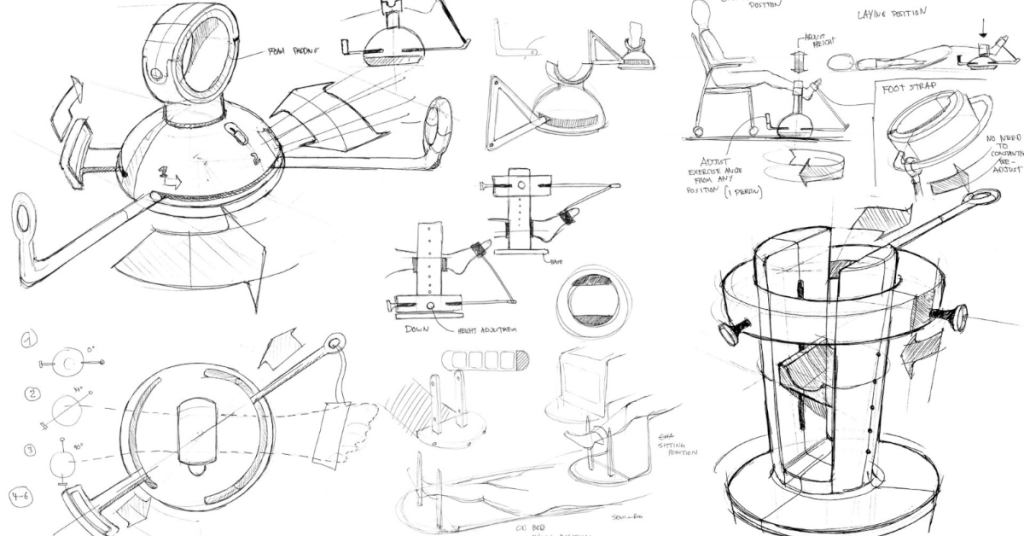

CONCEPT BUILDING

How can we solve it?

Concept Building is the second step in Design & Engineering, where ideas from the Ideation phase take shape. Here, we evaluate and develop the most promising concepts into practical design directions. Through sketches, CAD models, and feasibility analysis, we define form, function, and potential materials. This phase bridges creativity and engineering, ensuring that each concept not only looks great but also works efficiently and is ready for further development. It’s where ideas start becoming real, manufacturable solutions.

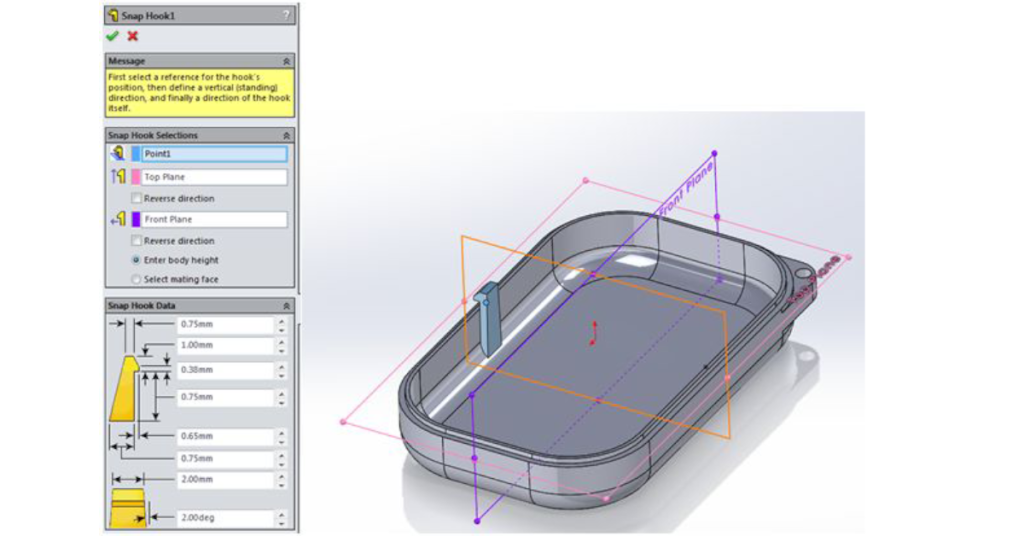

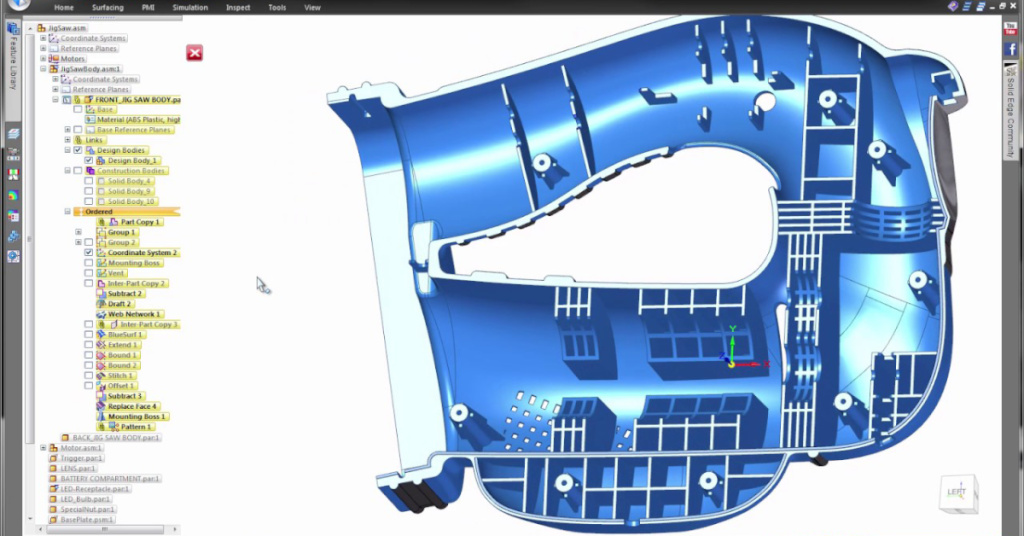

ENGINEERING

Give the idea a shape

Engineering is the third step in the Design & Engineering process, where ideas and concepts are transformed into detailed, functional designs. Using advanced CAD tools and technical expertise, we define every dimension, tolerance, and assembly detail. Materials are selected, components are optimized, and the design is prepared for manufacturing. This stage ensures the product performs as intended, is durable, and meets all requirements. Engineering gives the idea its final shape—ready for tooling, testing, and ultimately, successful production.

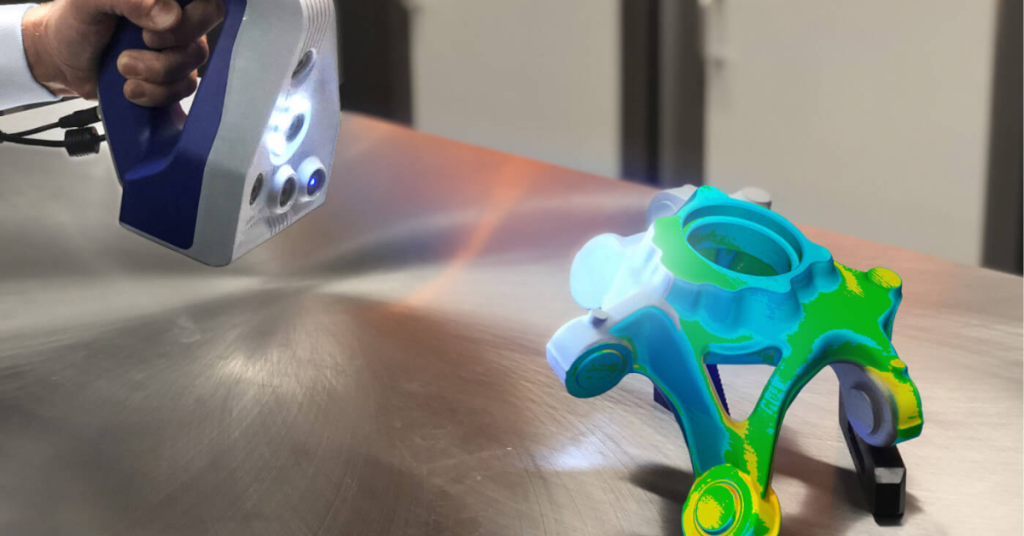

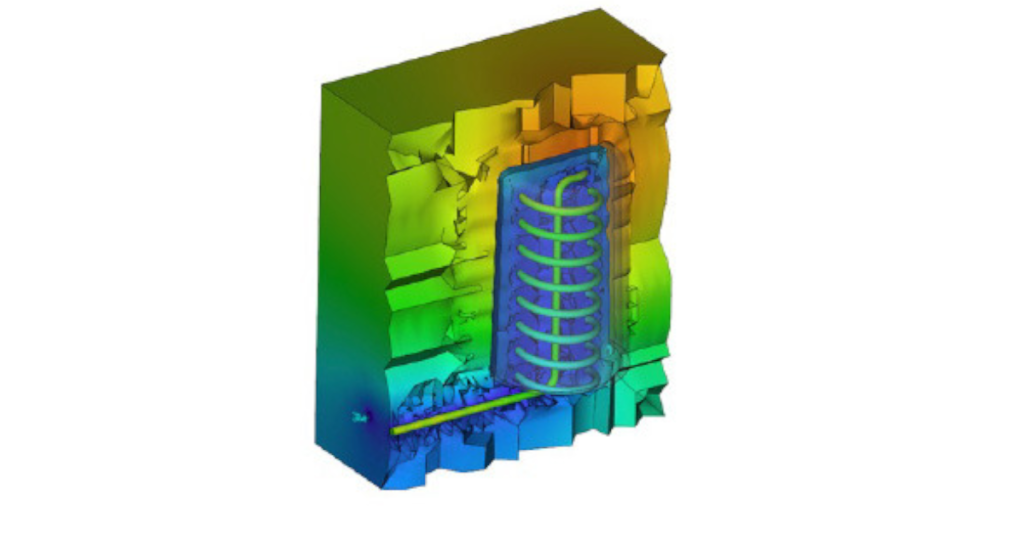

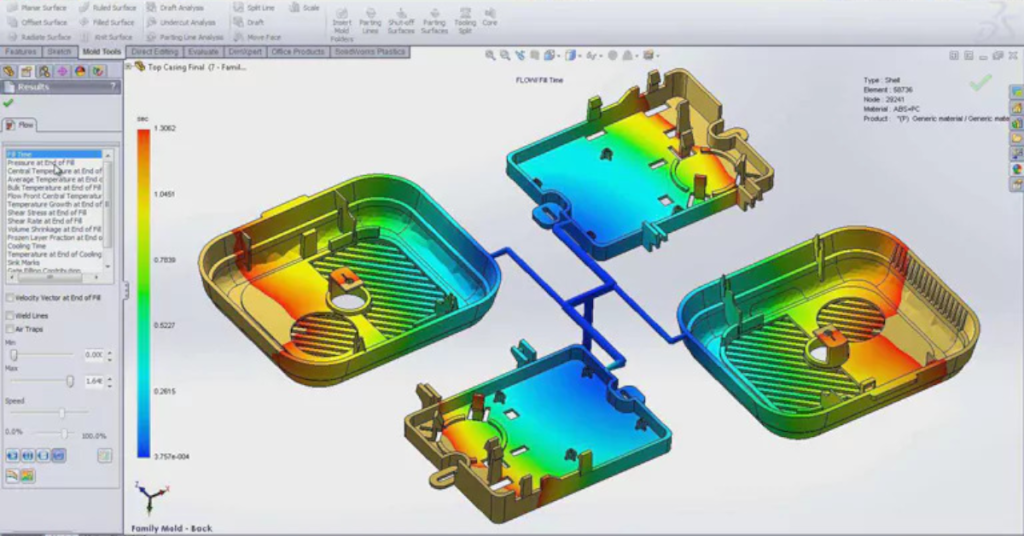

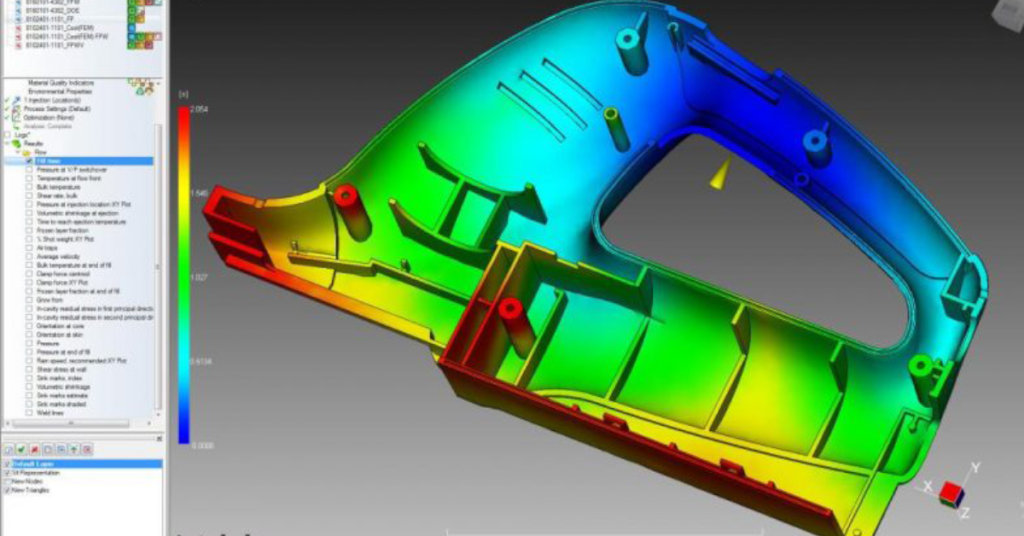

SIMULATION

Can this work? A first test in theory

Simulation is the fourth step in the Design & Engineering process, where we test the product virtually before it’s built. Using advanced software, we analyze mechanical stress, material flow, temperature behavior, and more to predict how the product will perform under real-world conditions. This allows us to identify and resolve potential issues early, reduce development time, and improve product reliability. Simulation ensures that the design works in theory—paving the way for a smarter, safer, and more efficient production phase.

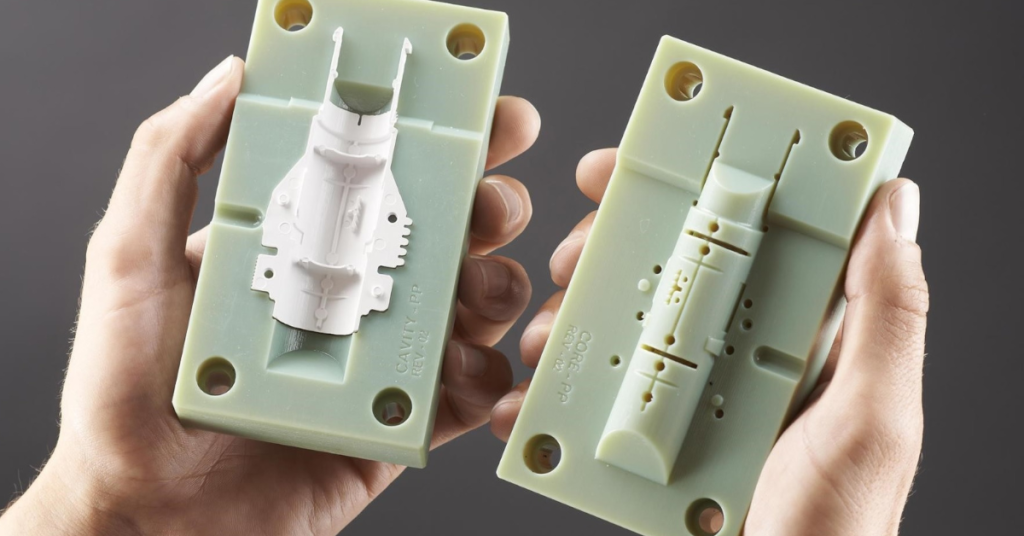

3D-PRINTING

Bring the Idea to reality - to touch and try

3D Printing is the final step in the Design & Engineering process—where ideas become reality. Using rapid prototyping technology, we transform digital models into tangible parts within hours. This allows us to test form, fit, and function before full-scale production begins. It’s a crucial stage for validating designs, making refinements, and showcasing concepts to stakeholders. With 3D printing, we bring your vision to life—quickly, accurately, and cost-effectively—turning innovation into something you can hold in your hands.

Product Gallery

Disposable Syringe

Plastic Moulders, Plastic Household Containers

Twisted Bottle

Vacumme Tube

Intrigued? Let’s explore more

Ready to turn your ideas into reality? Let’s build something great together