High-Quality Solutions Tailored for Your Needs

High-Quality Solutions Tailored for Your Needs

High-Quality Solutions Tailored for Your Needs

High-Quality Solutions Tailored for Your Needs

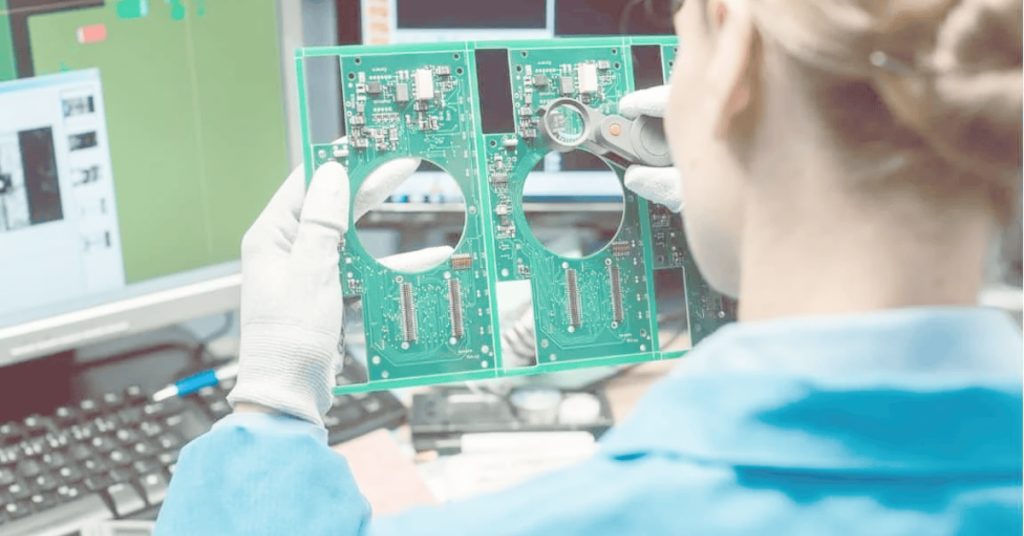

Precision-Crafted Plastic Solutions for Every Industry

At Kraftman Tooling, we don’t just manufacture plastic parts — we engineer precision, durability, and innovation into every product. With deep industry expertise and state-of-the-art technology, we produce high-quality components that power progress across sectors like automotive, medical, electronics, construction, packaging, and more. From everyday essentials to mission-critical parts, our plastic solutions are tailored to meet the most demanding requirements — ensuring performance, reliability, and efficiency at every scale.

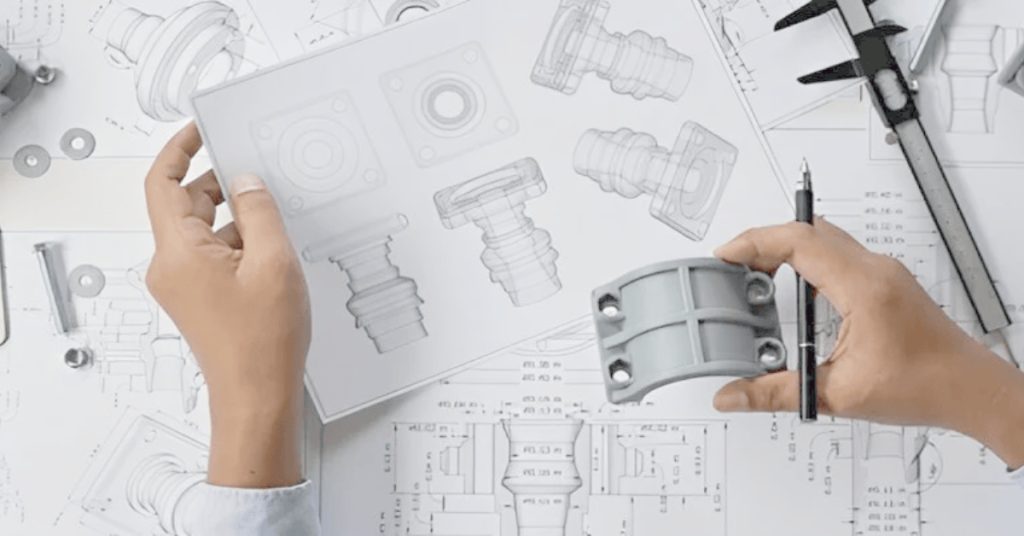

Engineering & Development

At Kraftman Tooling, every project begins with a strong foundation in innovation. Our Engineering & Development team brings ideas to life through a carefully structured process:

Ideation & Conceptualization: We collaborate closely with clients to understand their needs and transform initial ideas into workable concepts that align with market demands.

Engineering: Our skilled engineers use advanced tools to develop precise technical designs, ensuring functionality, durability, and manufacturability.

Simulation: Before moving to physical production, we run in-depth simulations to test and optimize the product design under real-world conditions, saving time and cost.

3D Printing: For rapid prototyping, we use 3D printing to produce accurate models that allow our clients to visualize, test, and fine-tune their designs before mass production

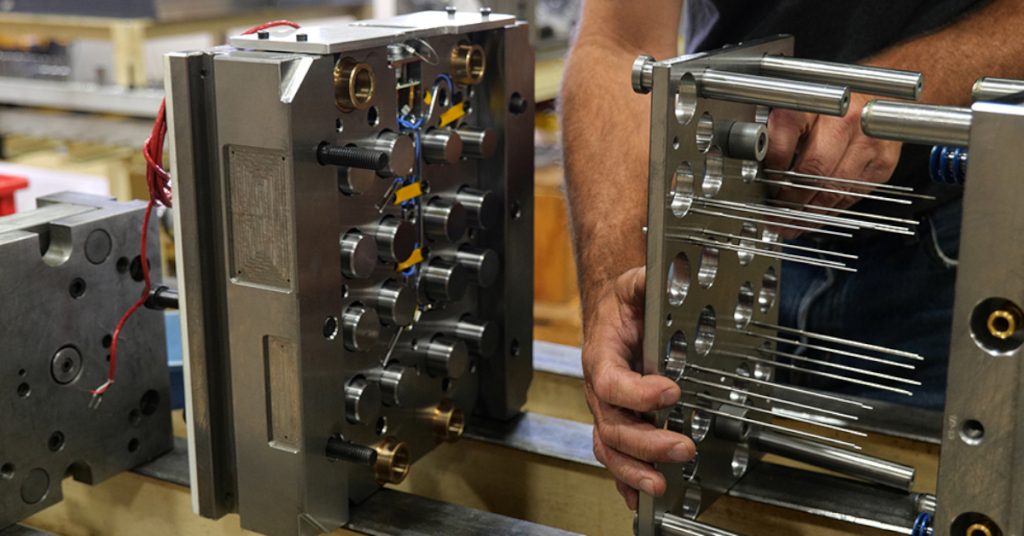

Mould Making

A streamlined process that transforms product concepts into high-precision injection molds through design, machining, assembly, and finishing.

Product Design Review – Analyze and optimize part design for moldability and performance.

Mould Design (Tool Design) – Create detailed 3D mold layouts tailored to production needs.

Machining the Mould Parts – Manufacture mold components using CNC and EDM technologies.

Assembly & Blue Matching – Assemble parts and ensure perfect alignment and fit.

Polishing & Surface Finishing – Enhance surface quality for optimal mold release and part aesthetics.

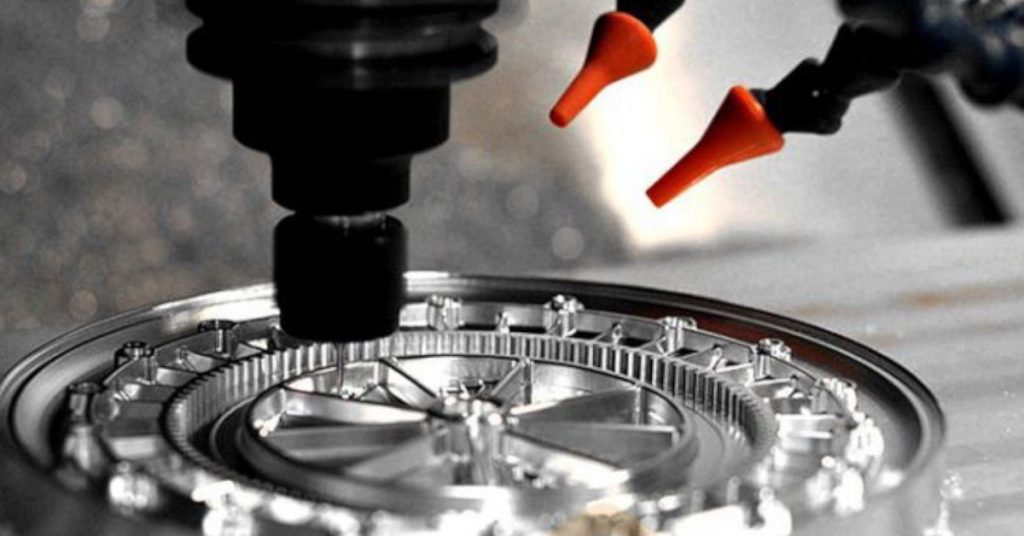

CNC Machining

CNC Machining: Precision in Every Cut

CNC machining transforms raw materials into high-precision components using computer-controlled processes that ensure accuracy, repeatability, and speed.

CNC Milling – Uses rotating cutting tools to remove material and create complex shapes, slots, and contours.

CNC Turning – Spins the workpiece while cutting tools shape the material, ideal for cylindrical and symmetrical parts

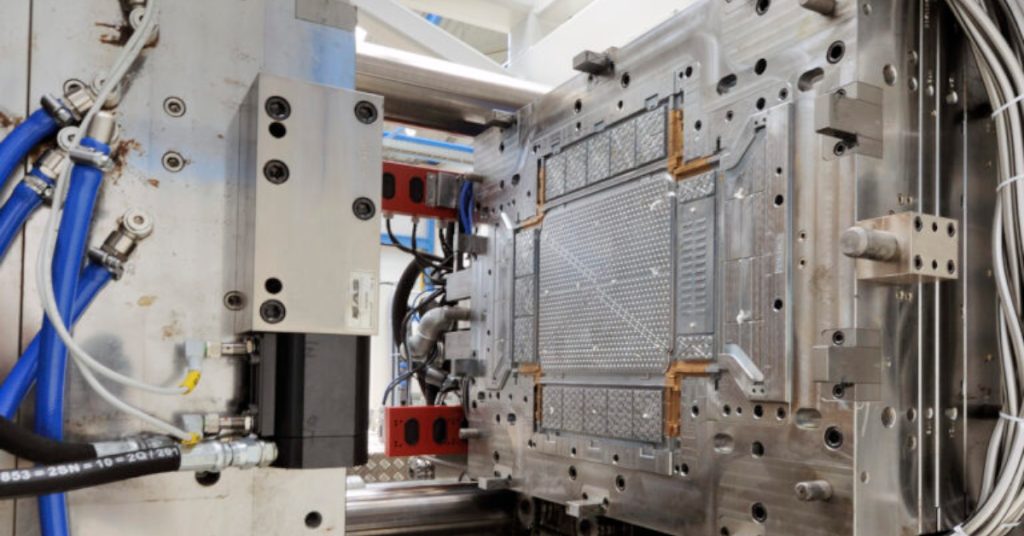

Molding

This is where the magic happens. Once the mold is ready, we bring the concept to life through efficient and high-quality plastic molding:

Realization of the Mold: Utilizing state-of-the-art injection molding technology, we turn the engineered design into physical components with precise shape, texture, and durability. Our process ensures consistency across batches, meeting even the most demanding industry requirements.

Decoration & Assembling

Beyond functionality, we help products stand out with expert finishing and assembly solutions:

Decoration:

Pad Printing: For detailed and durable printing on complex surfaces, ideal for branding and labeling.

Hot Stamping: Adds metallic effects and high-end finishes using heat and foil for a premium touch.

Spray Printing: Uniform and custom color applications for aesthetic appeal and product differentiation.

Chrome Printing: Achieves a metallic chrome-like finish, enhancing both look and corrosion resistance.

Assembling:

Thread Insert Application: Embedding threaded metal inserts to strengthen plastic parts where repeated fastening is required.

Seal Application: Ensuring tight, leak-proof seals critical for packaging and medical-grade products.

Packaging & Additional Services: We offer tailored packaging solutions and additional finishing tasks to ensure the final product is production-ready and market-presentable.

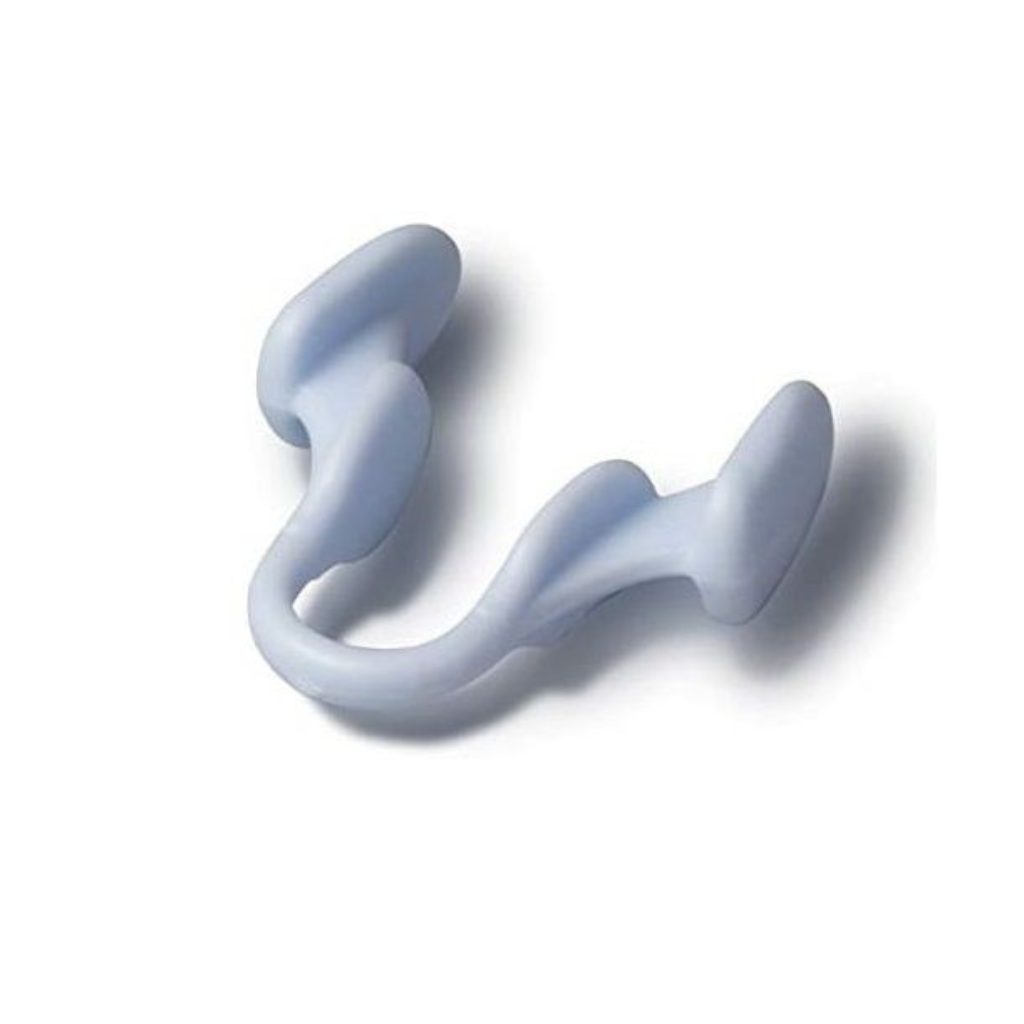

Product Gallery

From Concept to Creation – See Our Work in Action

Automotive Filter Clips

Food Container

Nasal Dilators

Plastic Square Mudguard Fastener Clips